|

Linear Actuators with

Optional Position Feedback

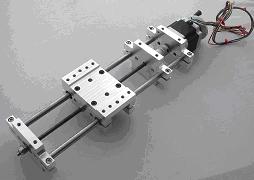

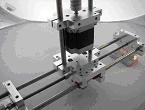

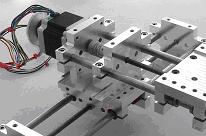

The Linear Actuator family consists of modular components made up of

end plates, carriage plates, carriage top plates, motor mounts,

flexible couplers, steel shafts, lead screws and thrust nuts. All the

mounting and end plates are made from T6061 Aluminum. Shafts are steel

and available in various lengths and diameters. These components can be mixed to

create linear actuators of different lengths and load capacities.

Actuators are available assembled or as individual components.

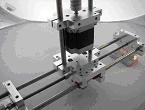

Linear actuators are available in

different lengths, shaft diameters and widths. Bigger shaft diameters

coupled with shorter lengths allow stiffer configurations.

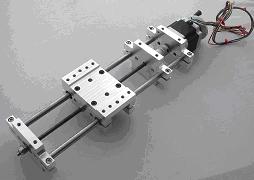

The modular nature of the design allows

simple assembly and replacement. Low cost threaded rod for the

lead screw keeps the cost low and is perfectly suited for many applications.

Lead screws are available in various diameters for lightly loaded X and Y axis

while larger diameters are used for heavier Z axis. Shaft and lead screw material can be

source locally, cut to length and installed.

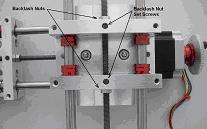

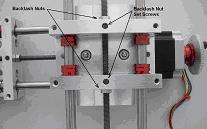

Opposing thrust

nuts mounted in the carriage end plates maintain tension on the

lead screw with minimal backlash. Lock nuts keep the bearings in place during operation. Teflon

or roller slide bearings can be used in the carriage assembly. The carriage

top plate is precision fit to the two carriage end plates with a center

depression and tapped mounting holes that accept adapter plates to mount

another Linear Actuator. A special nut on either side of the lead

screw eliminates the need for lead screw end preparation.

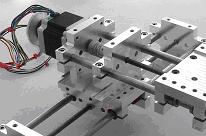

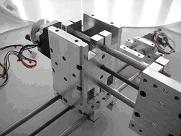

Adapter plates allow

two Linear Actuators to be precision mounted in various orientations to suit

a wide variety of applications. Grooves in the carriage plate fit into

ridges in the adapter plates ensuring a precise 90 degree mount. A second

linear actuator can be mounted horizontally or at right angles to the carriage

plate. Adapter plates enable rapid assembly of Cartesian robots or

mill configurations.

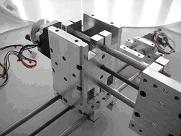

A new axis can also be mounted

vertically. The grooves ensure the axis line up exactly 90 degrees.

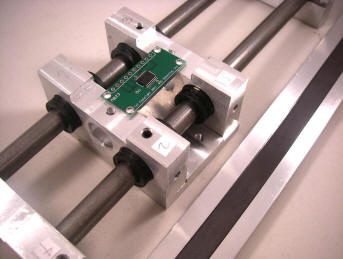

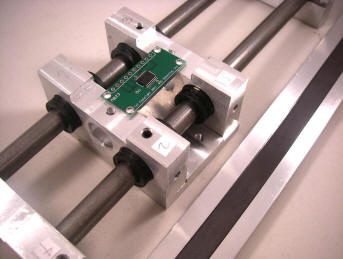

By integrating a magnetic strip and

sensor into the bottom of the LA real time position feedback of position

becomes possible. This feature can be added or not added - it's an

option.

By making the linear actuator design

modular it becomes possible to make LA's of different sizes to match the

application.

Pricing and order information will be on

the site shortly.

|